Zambia MSW & Country Data & Bright Future Project Brochure below

2018 – University of Zambia, Lusaka, Zambia – Brian Mushimbi report 2018.

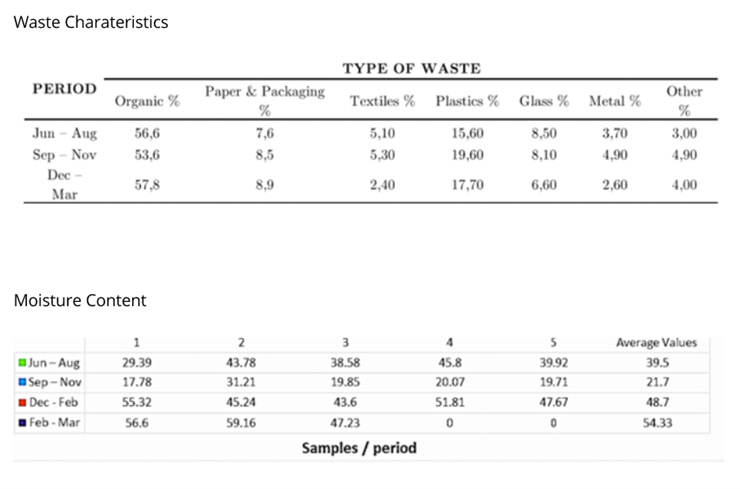

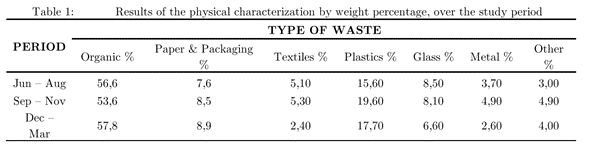

Municipal Solid Waste (MSW) characterization for Possible Waste-to- Energy (WtE) conversion in Zambia – Organics 56.6% – Plastic 15% – Paper & Packaging 7.6% – Textiles 5.1% – Glass 8.5% – Metal 3.7% – other 3%

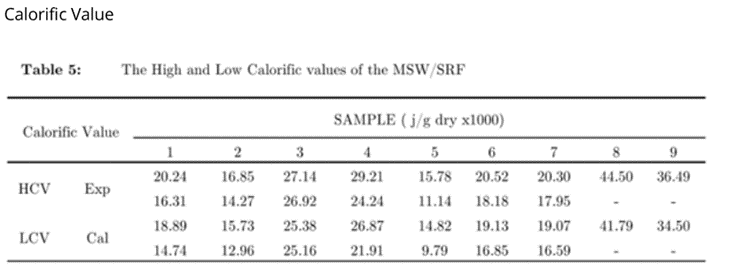

MSW studied had a high organic content (high in carbon content) of approximately 56% of the weight. High Carbon content implies corresponding high calorific values. The MSW studied had high value of calorific value of 21.43 KJ/Kg and low value of 18.43KJ/Kg. A requirement for MSW to qualify as a good substitute for coal is that its calorific values range between 16-18MJ/kg. The MSW found in Zambia meets the standard required to be classified as a high quality and usable alternate to coal in cement manufacturing in Zambia.

MSW studied had the highest moisture content in the months of December to March (Rainy season in Zambia) of 51.5%. The other months of the year had moisture content that averaged 30.6%.

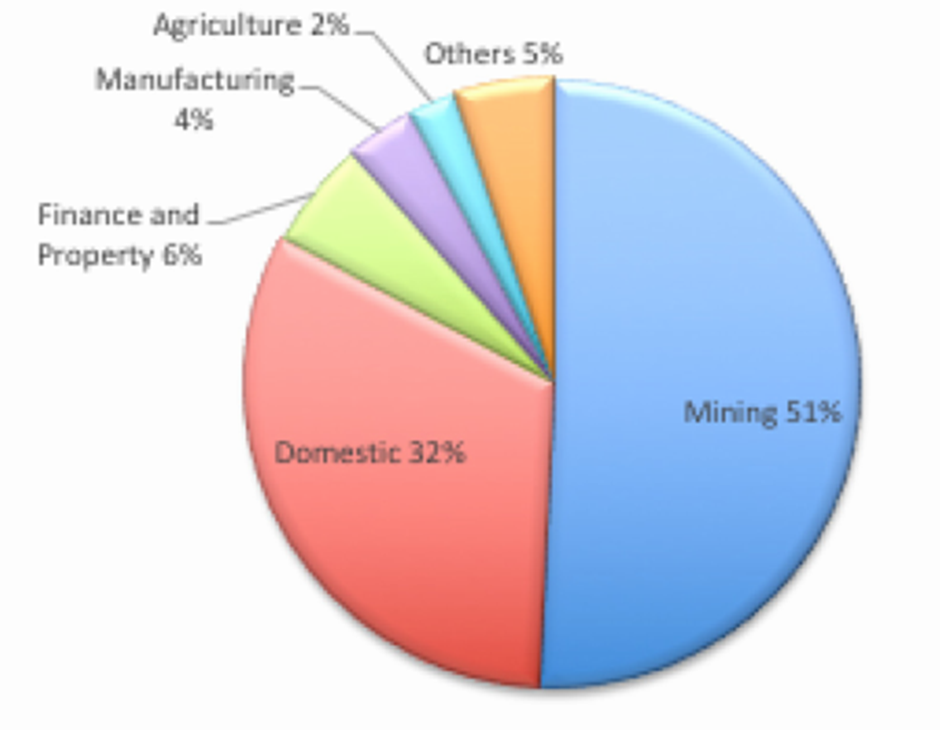

Energy Use in Zambia

Zambia Energy use above – with the adoption of the four waste plants and solar farms then the Zambia’s electricity security is enhanced – possibly leading to electricity supply 24 hours each day. The five plants will producing a total of 649,900 MWh of electricity each year.

Zambia MSW

We are providing four new waste plants for Zambia to process 2,000 tonnes per day (tpd) of MSW. Landfill waste being burnt on Landfill sites can be prevented now. Landfill waste increases in calorific value as waste degrades over the years – 23% increase due to organic fraction degrades. Also polluting the air and water through leachate entering the water will no longer happen in the future. There will be no need for anymore Landfill sites – the new Gasification & Recycling plants can now assist the Country Government in Zambia.

100% Recycling & Energy recovery

The Recycles glass, metal, ash and ceramics can now be used for manufacturing new goods. Ash, Glass and cement used for the manufacture of new building blocks for homes or ash and glass can be used for road surfacing. MSW plus waste oils, sludge and Medical wastes can be processed in the new plants. Recycled metals can be used for new factories to make new goods – Tyres can be processed and Rubber is reused in power production and steel recycled. Tomatoes and other crops can be grown in Green Houses close to the plant and using the waste carbon dioxide.

Each plant will require six acres of land.

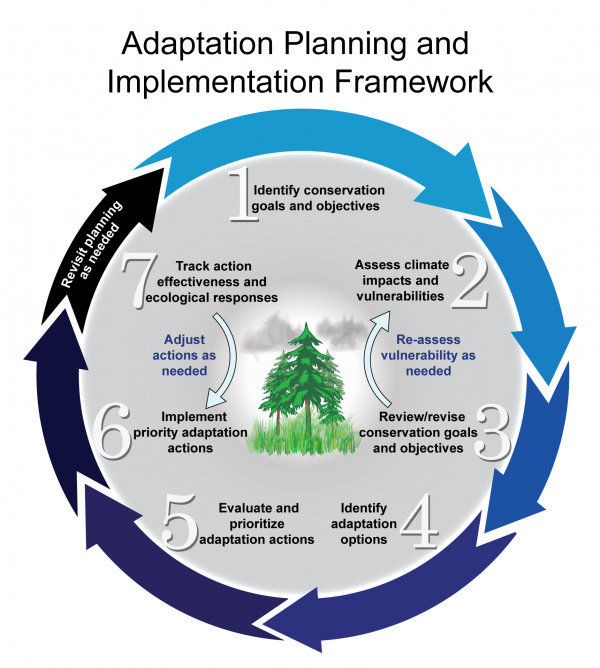

Circular Economy in action……

Circular Economy

Municipal Solid Waste (MSW) characterization for Possible Waste-to- Energy (WtE) conversion in Zambia – we have full details